Dow’s Fire & Explosion Index

The title reminds me about my thesis. And one of my lecturer disagree and attacks me with much questions about my thesis. But i really don’t care with him. I was interested in that title when i was in 5th semester. He told me it is like trash. Oh who do u think u are? Forget it.. And finally i got A for the final exam, I am so happy.

Back to the topic now. I wanna share my knowledge about one of method that used by some engineer to identification fire and explosion hazard. This metode usually used in oil and gas company or petrochemical company where the chemical always used for much activities.

Determine Process Unit

The important thing that you should ensure for choose the process unit :

Process Unit will result loss and catastrophic impact if fire and explosion occur. And another requirement is containing more than 600 gallons of flammable, combustible or reactive material which connected with other process units (not single design).

Reference from AICHE, Some factors that we must ensure are :

- Material Factor

- Quantity of Hazardous Material

- Catastrophic impact and fund density

- Operation condition (exactly : pressure and temperature)

- Past experience / accident (especially about fire and explosion)

Determine Material Factor

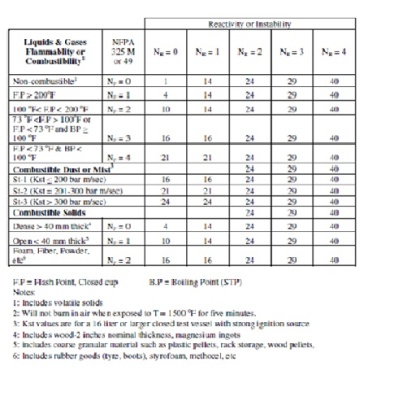

Material Factor give illustration about energy which is released because fire and explosion occur. how we can get value of material factor? it’s so easy, just multiplying value of reactivity (Nr) and value of fire (Nf). see this table :

Example : Gasoline

Gasoline has 3 for fire and 0 for reactivity (see NFPA 704), Gasoline is flammable liquid which will result of fire and explosion. So, Material factor of gasoline is 16 (see the table once again)

Determine General Process Hazard Factor (F1)

General Process Hazard is important for determine how big the fire will result? General Process Hazard Factor consist of six components.

- Exothermic Chemical Reaction

- Endothermic Process

- Material Handling and Transfer

- Enclosed or Indoor Process Units

- Access

- Drainage Spill Control

U must give penalty for all of components based on ur operation condition and design of equipment. Next step is adding all of penalty. And the result is score of General Process Hazard Factor.

Determine Special Process Hazard Factor (F2)

Special Process Hazard Factor is specific process operation which will expand incident probability and contribute with cause of fire and explosion occur. Special Process Hazard Factor consist of 12 components.

- Toxic Material

- Sub Atmospheric Pressure

- Operation in or near Flammable Range

- Dust Explosion

- Relief Pressure

- Low Temperature

- Quantity of Flammable / Unstable Material

- Corrosion and Erosion

- Leaking – Joint and Packing

- Use in Fired Equipment

- Hot Oil Heat Exchange System

- Rotating Equipment

U must give penalty for all of components based on ur operation condition and design of equipment. Next step is adding all of penalty. And the result is score of Special Process Hazard Factor.

Determine Process Unit Hazard Factor (F3)

Process Unit Hazard Factor is combination from General and Special Process Hazard. This factor usually contribute to fire and explosion occur. Determining this factor with multiplying General and Special Process Hazard.

Formula : F3 = F1 x F2

If the calculation result more than 8, u must use this score. Because the maximum score for F3 is 8.

Determine Fire and Explosion Index (F&EI)

Fire and Explosion Index illustrates level of risk in the process unit.

Formula : F&EI = MF x F3

where, MF = Material Factor, F3 = Process Unit Hazard Factor

From that table, we can determine level of fire risk in our process unit. Therefore, we can know what we should do to control that hazard.

Did u still remember about hierarchy of Hazard Control ?

- Elimination

- Subsitution

- Engineering Controls

- Administrative Controls

- Protective Personal Equipment

In this case, u can use engineering controls, administrative controls and protective personal equipment as hazard control.

Engineering Controls:

- Layout (Separate the process unit with others which will result catastrophic impact)

- Spacing (Giving space between process unit and public area), ref. refining safety code for minimum recommended separation distance

- Safety Device and Alert System

- Fire Detector

Adminitrative Controls:

- Work permit

- Job Safety Analysis

- Training

- MSDS

Protective Personal Equipment :

- Fire Retardant Clothing

- Self Contain Breathing Apparatus

Stay Safe, Stay healthy.

NO Harm, NO Hurt.

Posted on Agustus 27, 2015, in Fire. Bookmark the permalink. Tinggalkan komentar.

Tinggalkan komentar

Comments 0